News & Press

Intelligent Aircraft Wings Could Save Fuel

Chris Eberl develops unit cells – these miniature building blocks give materials special capabilities

Components no bigger than a particle of dust: the unit cells developed by micromechanic Prof. Dr. Chris Eberl at Freiburg’s Cluster of Excellence livMatS – Living, Adaptive and Energy-autonomous Materials Systems are barely a hundredth of a millimeter in size. The geometry of the cells helps to determine what can be done with the metamaterials they form. And at cruising speed, aircraft wings made of intelligent materials like this could morph in a way that enables them to minimize fuel or biofuel consumption.

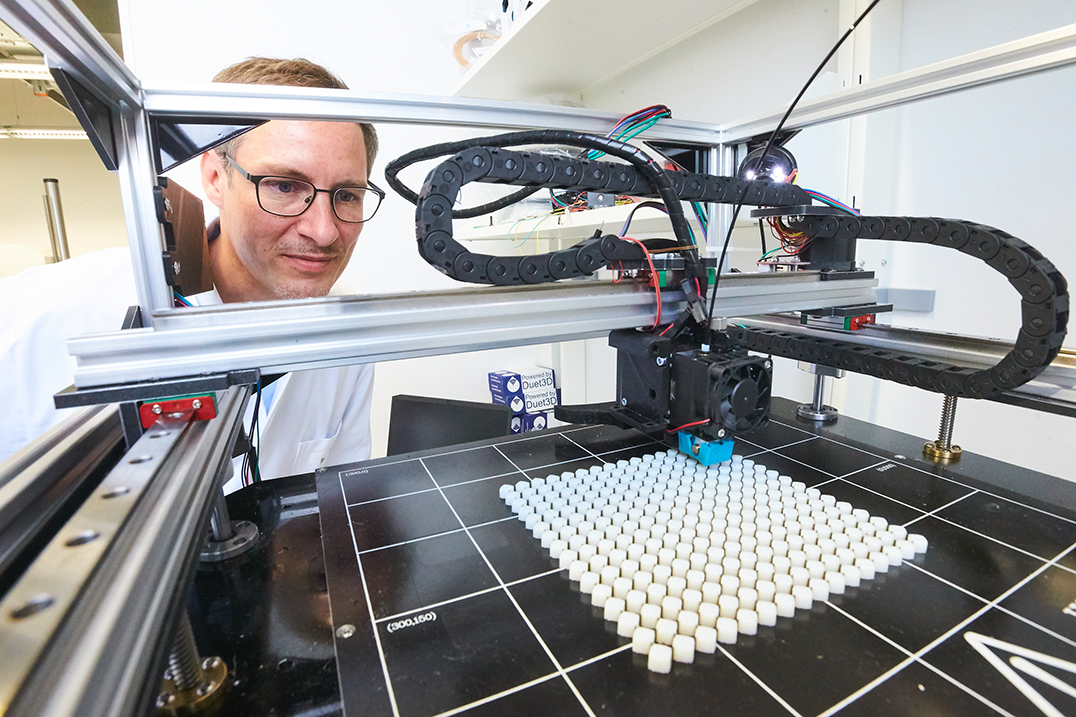

Components from the 3D printer: “shape morphing” of materials is one of Chris Eberl’s focuses.

Photo: Harald Neumann

The flight of aircraft could be more climate-friendly. “If their wings morphed in the right way at cruising speed, they could have improved aerodynamics and save on fuel,” says Chris Eberl. Professor of Micro and Materials Mechanics at the Department of Microsystems Engineering (IMTEK), Eberl is researching into intelligent materials. One theme of his work is “shape morphing”. Eberl, who is also deputy head at the Fraunhofer Institute for Mechanics of Materials (IWM), hopes to enable aircraft to morph their wings themselves. The idea is that they would recognize from the air resistance and other measurements when to make specific adjustments. “We are programming these capabilities into the structure of materials,” explains the scientist, “They should behave as if they were alive.”

Each unit cell meets its own needs

The researchers at livMatS are developing materials systems that adapt to external conditions, respond in the right way, learn and where necessary mend themselves. Eberl talks about “If/then relationships”: if air resistance reaches the value it has at cruising speed, then the wings morph. “We can program if/then relationships into the geometry of unit cells,” says the micromechanic. Unit cells are the smallest assembly units in his materials, like the bubbles in foam. He quickly displays a couple of designs – boxes in a variety of forms with elastic walls folded in various ways and with different strengths.

A different structure means different characteristics. Eberl can give unit cells many capabilities using their geometry. For instance they can cause materials to stiffen in spots under pressure, because only some of the unit cells morph – up to the point where the walls of reinforcements come up against one another. “In principle we could use the energy of pressure.” Instead of simply meeting up, under pressure wall reinforcements could lock into place like press studs on springs. A click, and the pressure energy would be stored. Then it would be released again when the “press studs” separated under specific conditions.

“The designs of the unit cells are based on experience, creativity, intuition and a lot of optimization,” explains Eberl, adding, “At the moment we can produce individual cells and are learning how we integrate a system into them.” There are a few barriers: unit cells are the size of fine dust particles. “They’re tiny, approximately ten micrometers – a hundredth of a millimeter.” In addition the cells interact with one another. To return to the foam comparison: when it’s put under pressure, the bubbles pass on parts of themselves to their neighbors. Each bubble morphs in a slightly different way. “It’s exactly the same - in intelligent materials each unit cell meets different needs,” stresses Eberl, “And we have to adjust each of them with considerable effort.”

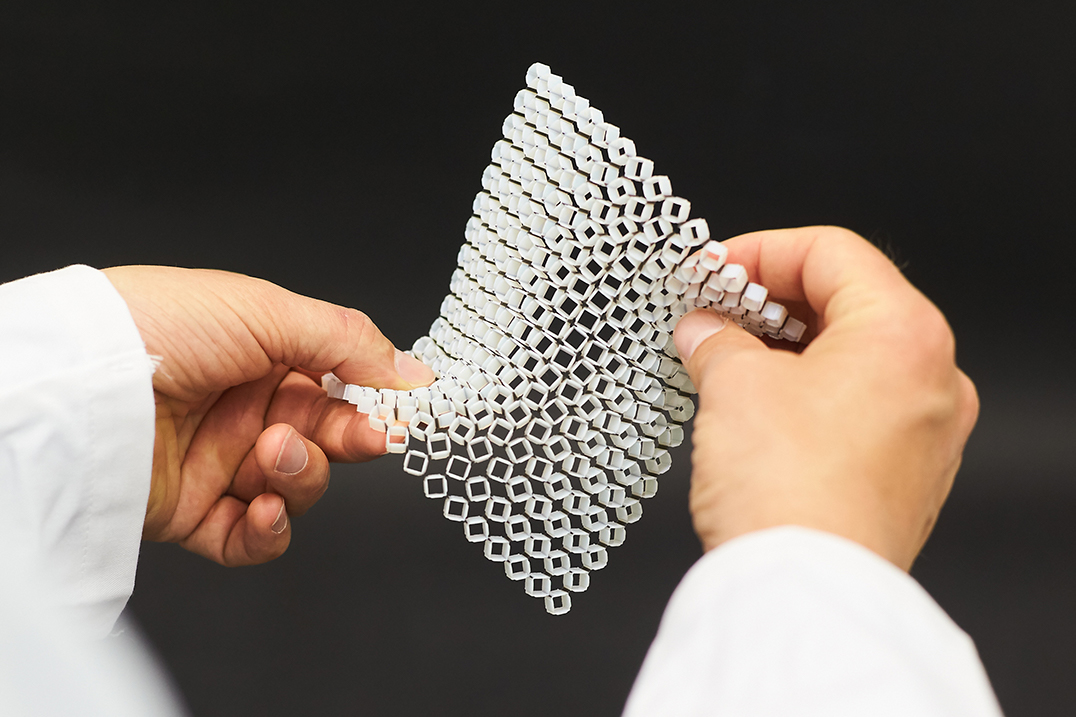

A model shows a network of unit cells: their substance should be non-toxic, recyclable and inexpensive. Photo: Harald Neumann

Non-toxic, recyclable, inexpensive

It’s only possible if the construction material is right too: “It depends on the material how fine the unit cells can be and how thick and stiff or flexible their walls become.” And the substance should be non-toxic, recyclable and inexpensive. After all, livMatS is aiming for sustainable, economic and industrial standard materials systems. So Eberl has to make sure that the production does not become too costly, including as regards methods. His team of ten produces the tiniest structures with two-photon lithography, an extremely precise 3D printing process. But it’s expensive! So larger components are produced using standard 3D printing and even larger mechanical parts using injection molding or foil processes.

And that’s not an end to it: the materials systems from Eberl’s cooperation projects have to work smoothly. Intelligent aircraft wings mustn’t deform as a result of brief, abrupt gusts of wind. The material has to be able to differentiate between interference and normality. And stability is required too. The wings should only morph at specific points, but they also mustn’t break there. And the list of criteria isn’t done yet: the materials systems are bioinspired. “We adopt concepts from nature, not to recreate them but to understand them fundamentally and adapt them to other purposes.”

That’s a lot to handle! “We see it as a challenge for the research,” remarks Eberl calmly. And it is precisely the scale and diversity of the disciplines engaged in the livMatS cooperations that enables it to pursue many goals: “There’s a lot running in parallel.” Cooperation partners develop new building substances, for instance, test cell types or simulate materials systems on the computer in detail at every scale: “So we understand them from molecule to component.” He mentions one more advantage of cooperation: “We can tackle projects more than just technologically.”

What does learning mean for materials?

The livMatS Cluster of Excellence looks at questions such as what learning actually means for materials. “A rod of relatively stiff material could learn to bend at just one point,” explains the micromechanic: repeatedly bending at that point could lead to molecules repositioning there, causing the rod to soften at that point and develop a point at which it should bend. So can you describe that as learning? “I don’t think so,” says Eberl. After all, the rod lacks feedback – the treat you give a dog when it does something right.

However, with all these demands self-flexing aircraft wings are some way off yet. But Eberl is hoping in two years to have a materials system that fulfills simple basic functions, and where possible is enduring, capable of being recycled and works reliably. To get there his cooperation partners will have to work flat out too: Dr. Olga Speck, a biomimeticist from the university’s Botanical Garden offers ideas and concepts from the plant world. Prof. Dr. Jürgen Rühe of IMTEK develops and optimizes structural materials. Prof. Dr. Lars Pastewka, also of IMTEK, models materials systems on the computer from molecule to component.

Jürgen Schickinger

Further articles in this series:

A Small, Sharp Eye

The Artificial Trap

Finding Words for the Space Between Nature and Technology

Close Proximity that Generates Energy